ATR 72 ICE AND RAIN PROTECTION

Understanding the ATR 72 Ice and Rain Protection System

Reading time: 10 mins

Welcome to the next installation of ATR Theories technical blogs, this time we are discussing the ATR 72 ICE & RAIN PROTECTION. Arguably one of the most important topics for this aircraft type. The nature of turboprops, thick wing, often unable to climb above the weather, cruising amongst the clouds, makes the ATR suspectable to ice build-ups.

There are many layers to the ICE & RAIN protection, so here’s a quick overview:

ICE Detection:

- A vibrating icing detector, connected to FWS, monitors ice accretion.

- Icing evidence probe, visible out the captain’s window.

Monitoring:

- APM (Aircraft Performance Monitoring) system triggers some alerts when the aircraft’s performance is degraded due to ice accretion on the aircraft.

Protection:

- Pneumatic de-icing boots located on:

- Wing leading edges, Horizontal tailplane leading edges, Engine air intakes.

- Electrical heating located:

- Propeller blades, Windshields, Probes, Flight control horns.

BASIC IN-FLIGHT PROCEDURES

Us as pilots break the ATR’s ice protection system down into 3 layers of protection – we call these “levels”.

“Level ONE” – Basic ice protection, and is always* selected after pushback.

- Includes electrical heating on the Pitot, Alpha (angle of attack), STAT (static air temp) and TAT (total air temp) probes AND front windshield heating. CHECK PROBES

“Level TWO” – ANTI-ICING, activated when flying into icing conditions (TAT below 7˚C and in moisture (cloud) inflight or 5˚C SAT on ground with wet conditions).

- Includes our electrically heated elements on the propeller blade leading edge, flight control horns and side windows.

“Level THREE” – DE-ICING, activated when in ICE ACCRETION is detected.

- Includes our pneumatically powered boots on the Wing leading edge, and horizontal tail plane leading edges, engine air intake leading edge.

*disclaimer – not SOP, just helps you understand the tech.

DETECTION – ANTI ICING ADVISORY SYSTEM (AAS)

The Anti-Icing Advisory System is made up of:

- Ice Evidence Probe (IEP) – visual indicator to both crew of ice accretion. Shaped like an aerofoil and incorporates a span wise edge to encourage ice accretion. Probe is illuminated by the NAV light switch. It is also used to confirm if the airframe is clear of ice.

- Ice detector probe* – mounted on the underside of the left wing leading edge. Powered by ACW BUS 2.

When 0.5mm of ice is accreting on the ice detector* the AAS prvovides a visual/aurual alert. The probe will then initate a heat cycle to remove the ice and start the detection again. However, the aural chime is inhibited when the de-ice boots are activated. The visual will illuminate regardless of boot status.

When ice accretion is detected:

- Master caution + single chime (unless boots are on).

- Amber “ICING” message appears on FMA.

- FMS automatically switches from NORMAL speeds, to ICING speeds.

Extinguished “ICING” doesn’t mean that the arframe is clear of ice, only that there is no ice accretion.

*Ice detector doesn’t detect super cooled water droplets.

ICING AOA PUSH BUTTON; *INSERT PICCY*

Illuminates green as soon as ONE of the HORNS Anti-icing pushbutton is selected ON, used to remind flight crew that the stall alarm threshold is lower in icing conditions.

When pressed:

- Icing AOA green label appears on FMA.

- Only turned off when by pushing the button again, when both horn anti-icing is OFF.

- Icing AOA is set OFF only when the airframe is clear of ice.

PNUEMATIC DE-ICING

The ATR uses de-icing boots to shed ice from the leading edges. This is done by periodically inflating a rubber chamber (boot) on the leading edge, as the boot inflates it breaks up the ice which is carried away by the air stream.

Boots are located on wing leading edges, horizontal tailplane leading edges, engine air intakes.

The system uses high pressure bleed air from the engines via a “de-icing valve”, supplied at 20.3 PSI, through a common manifold before being distributed to the boots. This allows the system to remain operative if on engine fails.

There are two inflating schedules depending on Static air temp (SAT).

- FAST MODE (SAT warmer than -20˚C) = 60 second sequence.

- SLOW MODE (SAT colder than -20˚C) = 180 second sequence.

There is a list of which boots are inflated when in the FCOM – if you can’t sleep 🙂

ELECTRIC ANTI-ICING

PROPELLER ANTI-ICING

Propeller anti-ice is performed by heating elements installed on the inboard sections of the blade leading edges. The system is supplied with 115 V ACW.

Two operating modes are available:

- AUTO: automatic operating mode. (button released).

- MAN: (button pushed in), MODE SEL is operative and available depending on the temperature. When selected on, the propeller anti-ice system starts to heat the blades only when NP (Propeller rotation) is sensed above 63%.

- NORMAL: used when SAT is between -10˚C and 0˚C. 60 second cycle

- ON: to be used when SAT is between -30˚C and -10˚C. 90 second cycle

Below -30˚C icing problems should not be present.

FLIGHT CONTROL HORN ANTI-ICING

Electric heating for the Rudder, elevators and aileron flight control horns.

– Flight contol horns extend ahead of the aileron/elevator/rudder and moves in the opposite direction, to help neutralise forces, making the flight controls lighter.

WINDOW HEAT

The cockpit windows are electrically heated:

- The front windshields for ice protection and defogging.

- The side windows for defogging only.

Common question to be asked in exams.

Front windshield: The 2 front windshields are heated by an electrically-heated transparent film that is sandwiched between the two plies of glass.

- Left front windshield powered by ACW BUS 1.

- Right front is powered by ACW BUS 2.

Two temperature controllers (one for each window) maintain the temperature of the outside ply above 2˚C, and the inside ply above 21˚C to prevent fogging.

Side windows: Are heated by small wires embedded between the two plies of glass. The windows are regulated to maintain the inner temperature over 20˚C.

- Left side window powered by 28 VDC DC BUS 1.

- Right side window powered by 28 VDC DC BUS 2.

Windshield heating fault:

- Master caution flashes,

- Single chime,

- Amber message on EWD,

- Fault light on L or R button. (lights are also illuminated during the MFC test).

CONTROLS

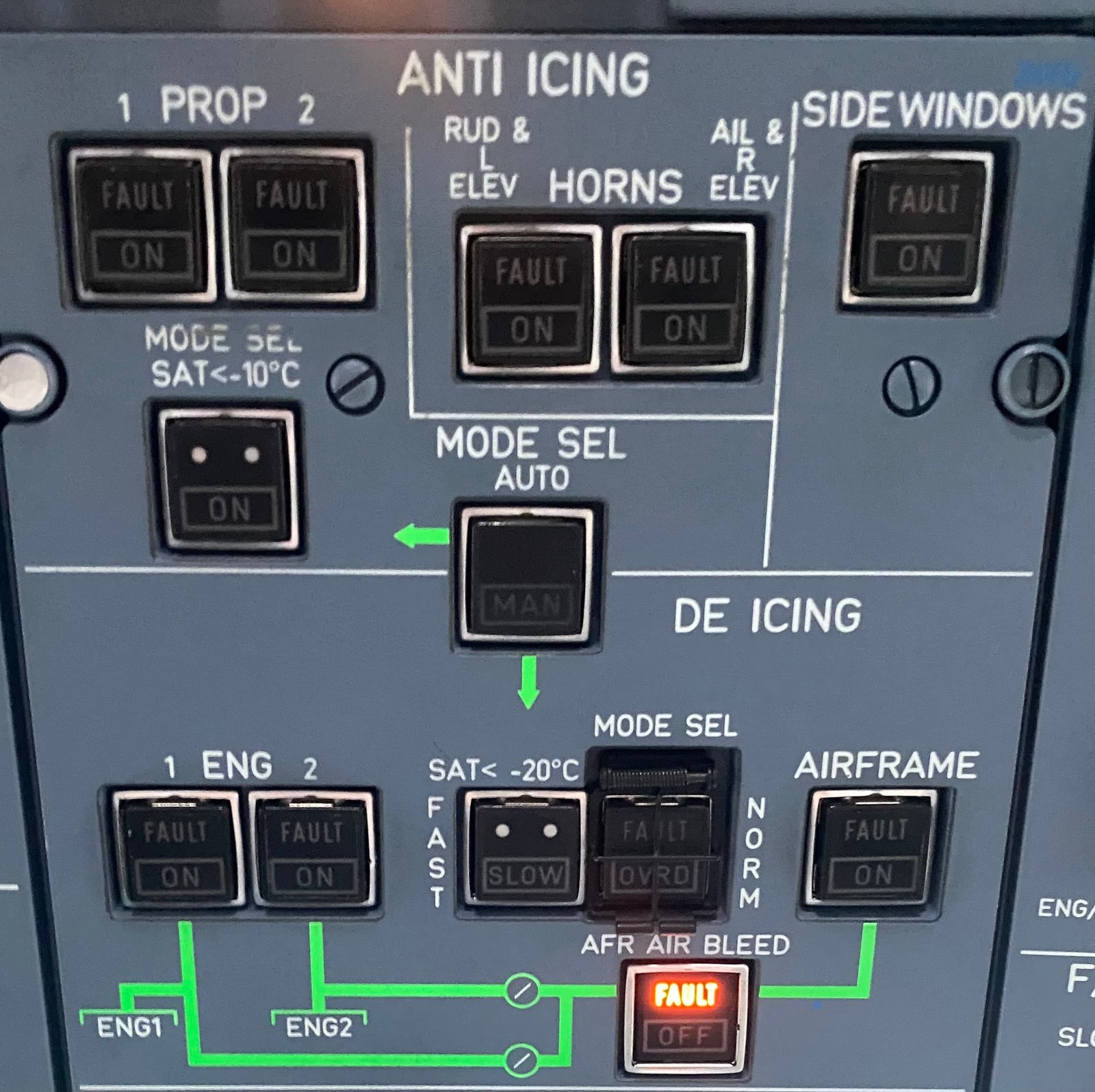

AFR AIR BLEED pushbutton

- Pushed, normal ops. Deice/Isolation valves open.

- OFF, deice/isolation valves close. (ENG de-ice can still be used).

- Fault (amber), Air pressure downstream of deice valves is less than 14 PSI, or the air temp upstream exceeds 230˚C.

AIRFRAME pushbutton

- ON, MFC initiates de-icing boot schedule. ON illuminates blue. Blue “AIRFRAME” on memo panel.

- Button released, associated boots stay deflated.

- FAULT (amber), when inflation sequencing of airframe boots isn’t correct. Master caution, single chime, “AIRFRAME” in amber on EWD.

ENGINE (ENG 1/2) pushbutton

- ON, MFC initiates de-icing boot schedule. ON illuminates blue. Blue “ENG§” on memo panel. Even if AFR AIR BLEED is not selected ON.

- Button released, associated boots stay deflated.

- FAULT (amber), when inflation sequencing of airframe boots isn’t correct, upstream of de-ice valve exceeds 230˚C with AFR BLEED OFF. Master caution, single chime, “ENG” in amber on EWD.

DE-ICING SAT < -20˚C pushbutton;

Used when SAT is cooler than -20˚C, controls the selection of wings/engines boot cycles when MAN is selected on MODE SEL AUTO pushbutton.

- FAST (released) cycle is 60 seconds.

- SLOW (button pushed in) cycle is 180 seconds.

DE-ICING MODE SEL guarded pushbutton;

- NORM; normal ops.

- OVRD; The emergency de-icing activation is selected (60 second cycle), used when a FAULT occurs.

- FAULT (amber); occurs when both MFC modules associated with air intake boots control fail. Master caution, single chime, “A-ICING SEL” on EWD.

DE/ANTI-ICING MODE SEL AUTO pushbutton

- NORM (button released); normal automatic operating mode.

- FAULT (amber); The De-icing mode sel pushbutton is inoperative and FAST mode is automatically activated.

- MAN (blue); the flight crew must select the boot cycle depending on the static air temperature.

HORNS pushbuttons

Electric heating for the Rudder, elevators and aileron flight control horns.

- ON, system activated, illuminates cyan + “ICING AOA” on the ice detector panel.

- OFF, system off.

- FAULT, when electrical power is lost on of the associated systems.

Horn heating is inhibited whilst on the ground.

PROP (1/2) pushbutton;

- ON; Heating elements are powered.

- Button released; heating elements not supplied.

- FAULT (amber); indicates at least one blade is not supplied. Master caution and single chime.

MODE SEL SAT <-10˚C pushbutton;

Controls the duration of prop anti-ice cycles when MAN is selected ON.

- Button released; LOW POWER cycle is selected, used when SAT is warmer than -10˚C.

- ON; High power cycle is selected, to be used when SAT is between -30˚C and -10˚C.

MODE SEL AUTO pushbutton;

- FAULT (amber); The De-icing mode sel pushbutton is inoperative and HIGH power mode is automatically activated.

- MAN (blue); the flight crew must select the timing cycle depending on the static air temperature.

RAIN PROTECTION

Wipers remove rain from front windshields.

- Each wiper is driven by a two speed DC electrical motor.

- Capt’s wiper powered by DC ESS BUS.

- FO’s wiper is powered by DC BUS 2.

When the OFF mode is selected, the wiper automatically parks.

LIMITATION: Wipers shouldn’t be used when airspeed is above 160kts.

AIRCRAFT PERFORMANCE MONITORING (APM)

The APM system monitors aircraft drag whilst in icing conditions, and compares the aircraft theoretical drag with the current drag and alerts the flight crew if a reduction of aircraft performance occurs. Monitoring starts after landing gear and flap retraction and continues during the flight whilst in a clean config.

APM Inputs:

- Pressure altitude,

- SAT,

- IAS,

- Engine torque,

- Propeller rotation speed,

- Landing gear and flap sensors,

- Aircraft weight derived from the FMS.

- Altitude hold mode.

The APM warnings are activated when:

- The airframe de-icing is selected on,

- The ICING AOA light is illuminated,

- Ice accretion is detected.

- The static air temperature is below 10˚C,

- Both engines are operating,

- And the flaps and gear are retracted.

Warnings:

- Degraded performance; When there is an abnormal drag increase (22-28%) that could be due to severe icing conditions, speed is lower than ICING BUG + 10kt, the system provides a DGD PERF caution warnings on EWD & FMA, 2 master cautions + single chime.

- In climb, alert is triggered by an increase of drag that generates a drastic reduction of vertical speed.

- In cruise, alert is triggered by an increase of drag that generates an IAS drop (15-20 kts below the expected cruise speed).

- In descent, the alert is triggered by a drag rise.

- INCREASE SPEED; alert is triggered by a severe performance degradation generating an IAS drop below ICING BUG + 10 kt. Generates master cautions, single chime, “INCREASE SPEED” on FMA & EWD.

- Cruise speed low; (CRZ SPD LO); when aircraft is in cruise mode, the airspeed is 10 kts less than the max cruise speed, and there is a small drag increase. Generates amber “CRZ SPD LO” on FMA, no aural alert.

FAULT master caution; due to internal failure or invalid aircraft parameters. Fault detection is inhibited when the aircraft is on the ground.

That’s the end of this techincal blog on the ATR 72 ICE AND RAIN PROTECTION systems. There’s a lot of text there, but I have captured the key points as best I can, until next time 🙂

0 Comments